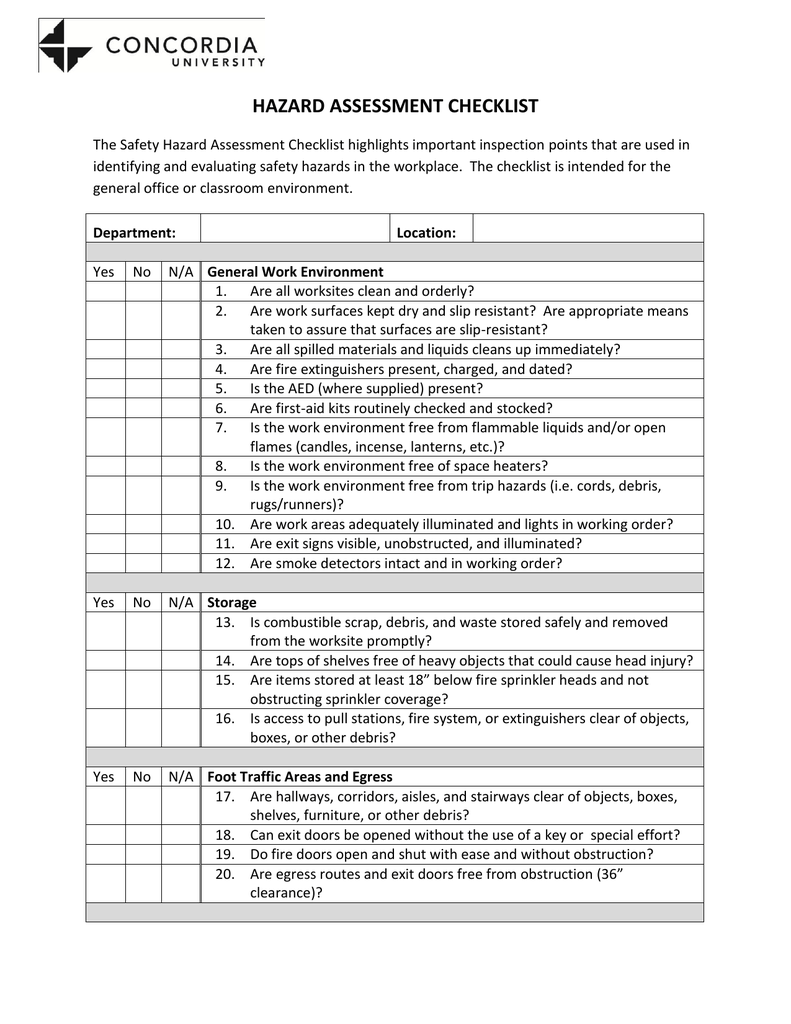

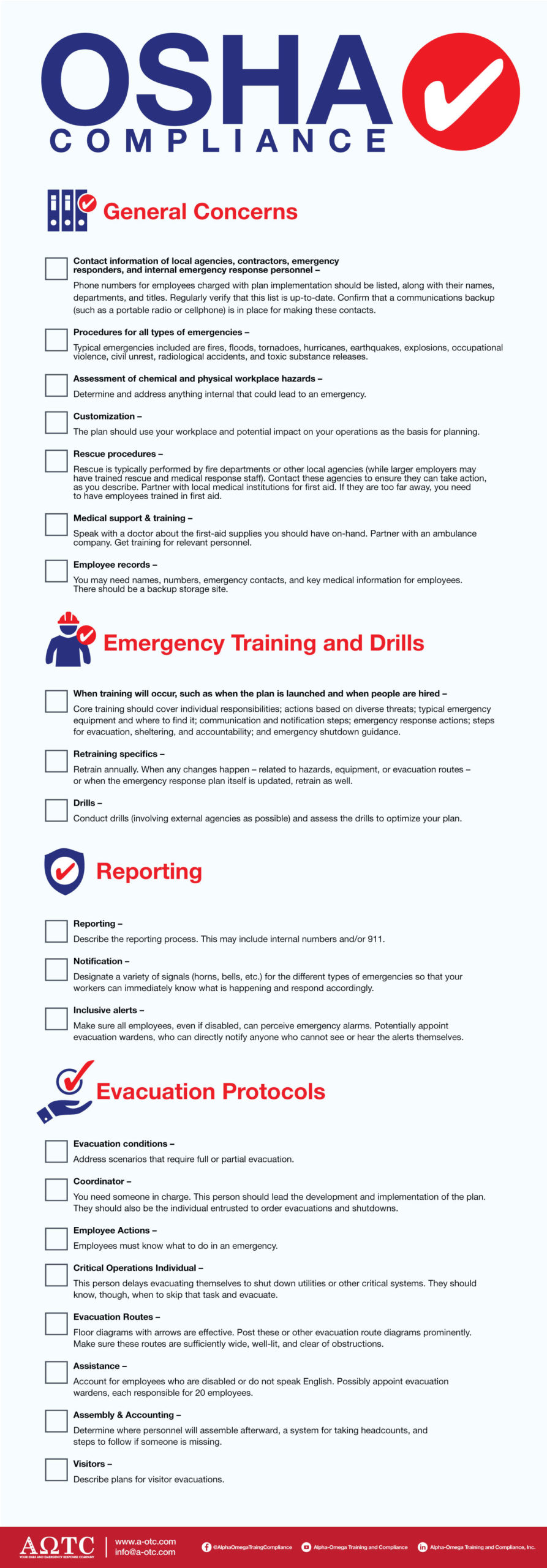

However, it is considered a best practice for companies of all types to have safety checklists, and they are particularly important for organizations in potentially hazardous sectors, such as manufacturing and construction. OSHA does not require businesses to have a workplace safety inspection checklist. Does OSHA require a workplace safety inspection checklist? Safety professionals use inspection checklists to conduct periodic self-inspections to ensure general safety and prepare forOSHA inspections. In practice, this means that checklists can vary in length and complexity based on business type and size. Safety checklists include common work hazards as well as safety requirements that pertain to specific industries. What is a workplace safety inspection checklist?Ī workplace safety inspection checklist is a simple tool that safety professionals use to help ensure that job sites adhere to safety requirements and that workers follow safety practices and procedures.

#Osha safety checklist how to#

In this guide, you'll learn about what should be included in a safety checklist and how to proactively identify safety violations with Site Visibility technology. An inspection checklist is critical in keeping workers safe and preventing violations-as well as minimizing the fines they can bring. If OSHA finds a serious violation, the agency can levy fines of up to $14,502, while repeat violations can bring penalties of up to $145,027 per incident.Ī workplace safety inspection checklist provides a definitive overview of the top safety concerns that need to be monitored on a job site. In 2021, OSHA safety inspectors completed more than 24,300 safety checks at worksites across the United States. If you have any doubts or questions about the operation of a particular piece of shop machinery, never hesitate to ask your supervisor or a qualified co-worker.After hitting a low point in 2020, the Occupational Safety and Health Administration (OSHA) is conducting an increasing number of safety inspections.

Never cut corners because you think it’s going to save time.

#Osha safety checklist free#

This is usually a good time to submit purchase requisitions for replacements cords, guards and other worn or damaged equipment, such as a scratched face shield that users can hardly see through.

#Osha safety checklist portable#

Periodically check all hand tools, portable power tools and larger shop equipment.Check emergency equipment such as first aid kits, emergency lighting, fire extinguishers and eye wash stations monthly.It goes without saying that you should never leave a machine in operation while it is unattended. Secure the shop when no one is present.Do not allow unauthorized persons to visit or loiter in the shop. Under no circumstances should unapproved people be allowed to use the shop equipment.The following are common, important safety guidelines to remember when working in the shop environmen. In OSHA, OSHA Safety, OSHA Training, Safety, Safety Manual, Safety Talk, Safety Toolbox Talks, Safety Toolbox Topics, Safety Topics, Tailgate Safety, Tailgate Safety Meetings, Tool Box Talk, Toolbox Talk Topics, Toolbox Talks, Toolbox Topics

0 kommentar(er)

0 kommentar(er)